Monitor Your Highly Corrosive Scrubber Systems With Ultrasonic Technology

Ultrasonic technology is an ever-evolving technology that has been used in many industries, including the food industry. Ultrasonic technology can be used to monitor your highly corrosive scrubber systems with ultrasonic technology. You can learn about various types of technologies and their usage, on this website: statlab-dev.com

Ultrasonic technology is used to monitor the surface of a material. This is done by sending out ultrasonic waves and listening for the echoes that bounce back to you. These echoes contain information about the material that you’re monitoring, such as its composition and its thickness.

Table of Contents

The benefits of using ultrasonic technology include:

The ability to track multiple materials at once

The ability to distinguish between different materials without having to take an actual sample of the material itself

A lower cost than other detection methods

Ultrasonic technology is an excellent tool for monitoring the performance of your highly corrosive scrubber systems. Ultrasonic sensors are able to detect even the slightest change in pH and pressure, which can indicate a failure in the system. By using ultrasonic sensors you can monitor the health of your highly corrosive scrubber systems and identify any issues before they become serious problems that require expensive repairs or replacement.

Ultrasonic technology is a great way to monitor your highly corrosive scrubber systems. Ultrasonic sensors have the ability to measure water flow and the presence of corrosion products. The problem with traditional testing methods is that they are slow, cumbersome and expensive. Ultrasonic technology has all of these attributes, but it also has an added advantage over other testing methods in that it does not require any special equipment or setup.

Ultrasonic sensors are small devices that can be attached to any type of pipe or ductwork. They are placed on either end of the pipe or duct, measuring the amount of water flowing through it in both directions. This information can then be used by plant operators as they make adjustments to their systems based on changes in flow rates or water quality.

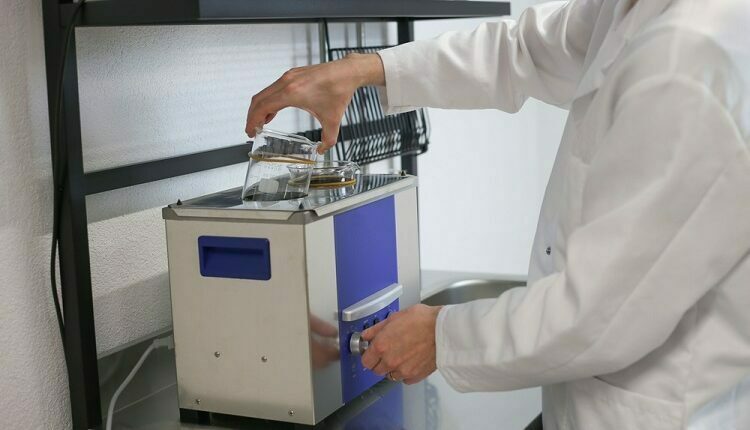

Ultrasonic technology is a monitoring and inspection tool that can be used to monitor the highly corrosive scrubber system. Ultrasonic technology has been used for years to monitor the health of plants, water and even people. The technology utilizes sound waves to analyze materials, allowing it to detect changes in the materials that could potentially lead to failure or damage.

The ultrasonic technology works by sending out high frequency sound waves through materials, which are then received back at their original location by a receiver. This produces an echo of sorts, which can be used to determine if there is an issue with the material being monitored. For example, if there is a problem with a pipeline and water pressure is low, you might hear an echo that indicates there is something wrong with either the pipe or your water supply line. You can click here to find out more on ultrasonic. You can learn about the amazing technologies that are being used in different regions of the world, on this website: techNolik.com